Industries

The Thermo Systems engineering team offers design, construction, and life cycle service expertise in our 3 key markets:

Energy & Utilities

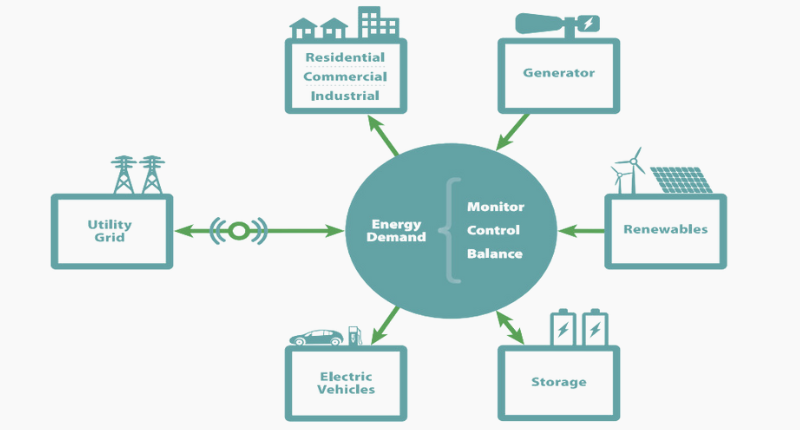

Within the Energy discipline, Thermo Systems has in-depth experience designing, building, optimizing, and commissioning control systems for chiller plants, boiler plants, cogeneration facilities, energy transfer stations, electrical microgrids, and city-wide SCADA networks. Thermo Systems designs and deploys non-proprietary hardware and software solutions utilizing manufacturers such as Rockwell Automation, GE, OSI, Schneider Electric (Wonderware) and others.

Life Sciences

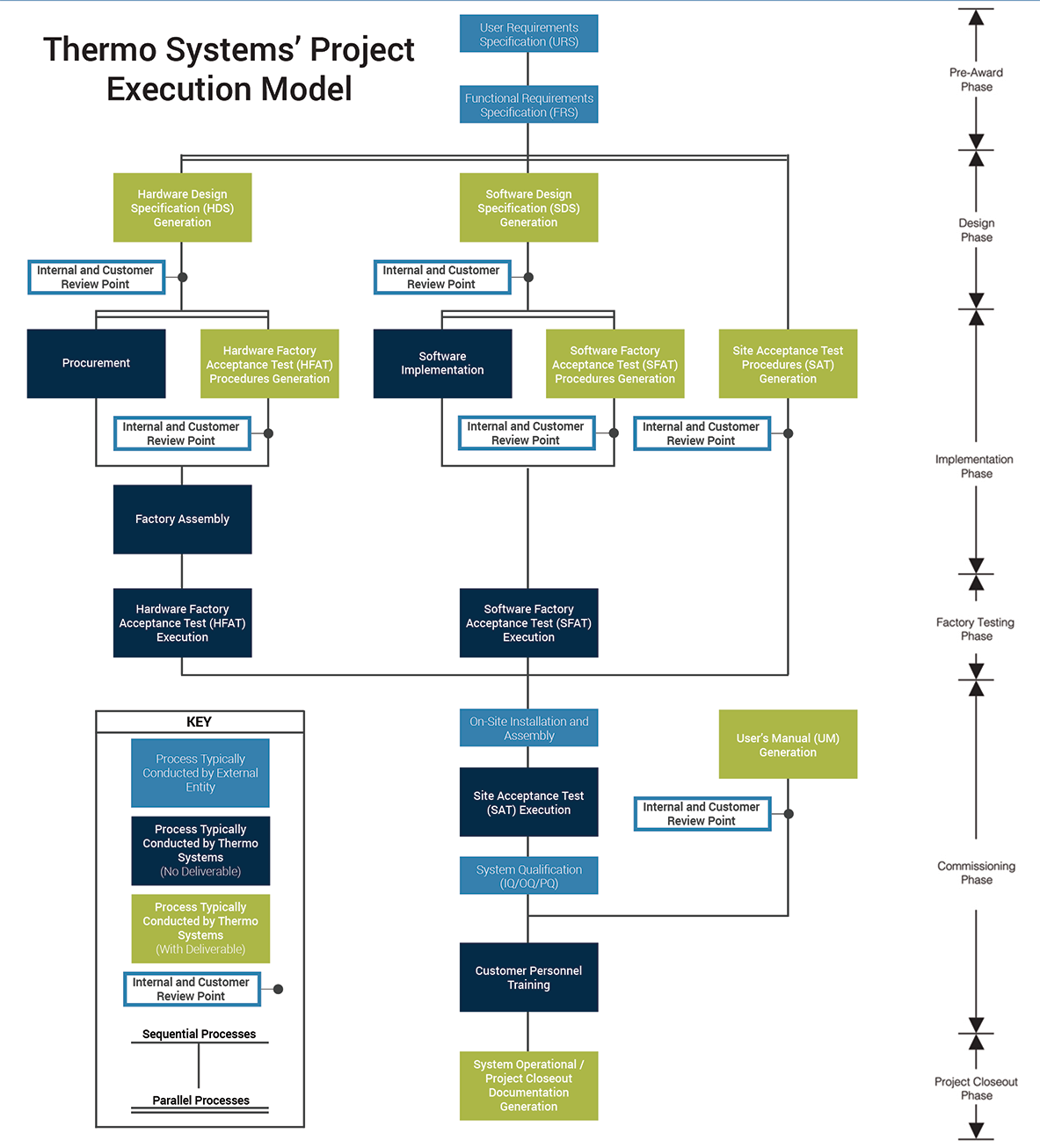

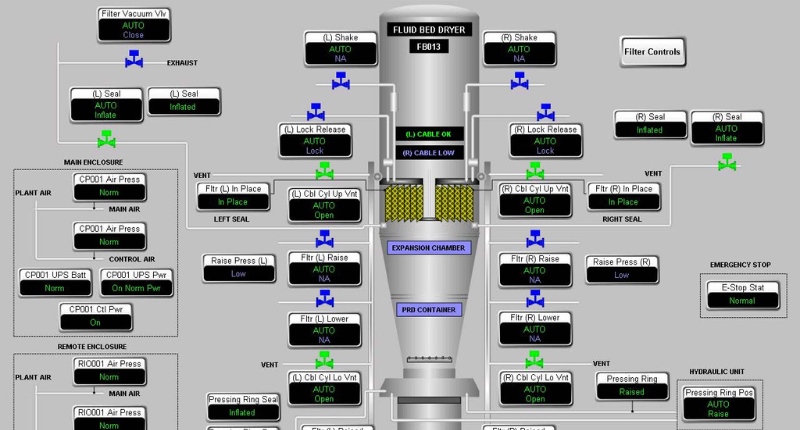

Our engineering model is based on the GAMP-5 standards for automation and information systems in GMP environments. Our engineering team is well versed in the development and execution of validated projects and has proven capability and domain knowledge in everything from raw materials through finished goods, including process utilities. As a full-service control systems integrator, we are responsible for all tasks required to define, design, build, implement, test, and commission our projects. In addition, we provide customer training and post-project 24/7 services. Our extensive experience allows us design, build, and deliver automation and information systems for your labs, manufacturing facilities, and utilities areas.

Mission Critical

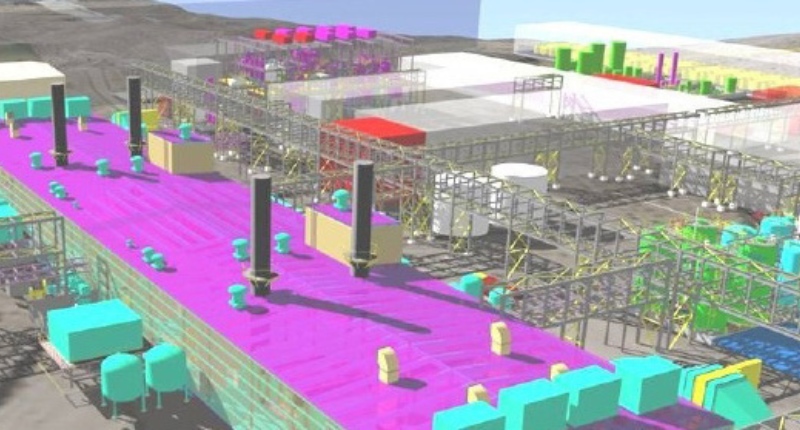

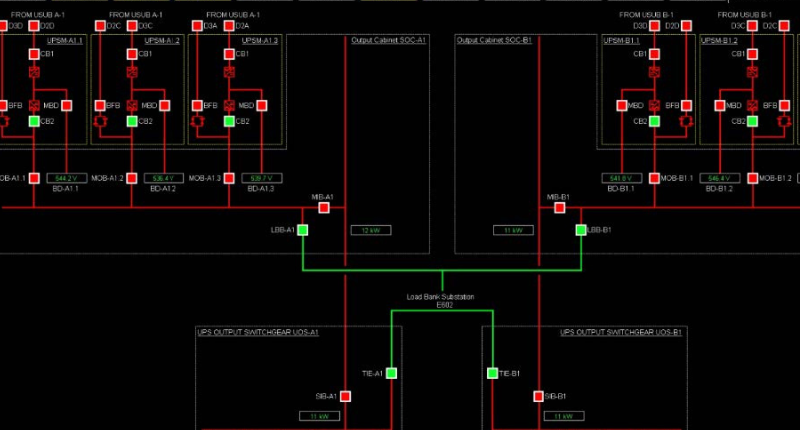

The data center industry is experiencing rapid growth, and Thermo Systems has extensive experience designing and installing the control systems to make their facilities and critical utilities both efficient and resilient. We have expertise in data center cooling & chiller plants, industrial building automation systems (BAS), power/electrical management systems, SCADA & historian systems, fuel distribution systems, and more.

Controls for Energy & Industrial Utilities

A more efficient, resilient, and green solution

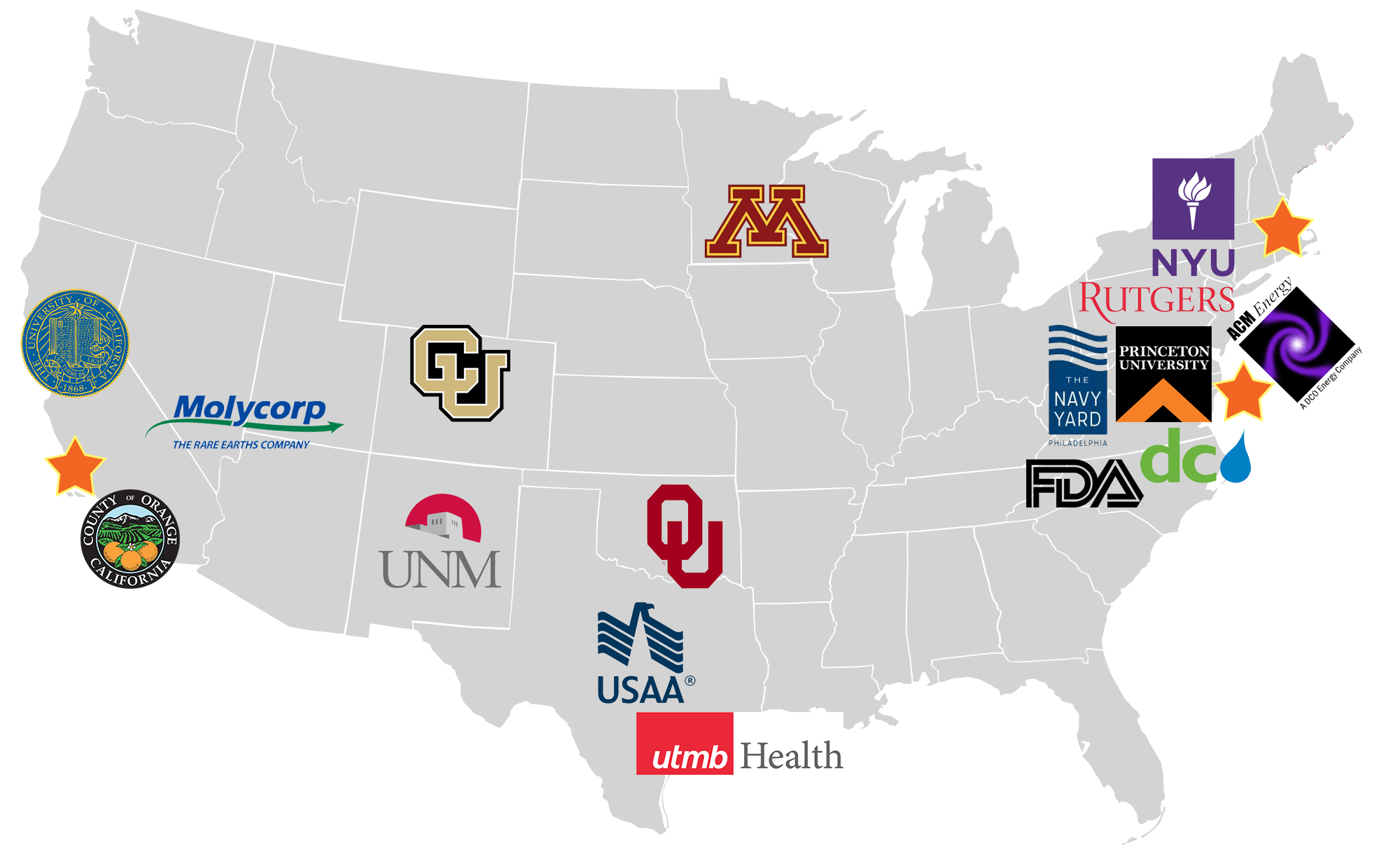

Thermo Systems is a leader in providing balance of plant controls for energy systems. District energy is a proven technology that has been around for decades. Most major cities, university and corporate campuses, and hospitals and other critical buildings receive their heating and cooling from a district energy system. This allows the heating, cooling, or both to be distributed to multiple buildings from one central energy plant which can be located underground, on the roof, or in a connected facility. A district energy system creates greater efficiency by regulating the flow of energy from building to building, and it creates a cleaner solution by minimizing wasted energy. Many organizations with industrial facilities have turned to district energy to make their operations more efficient, resilient, and sustainable.

Energy Expertise

Within the Energy discipline, Thermo Systems has in-depth experience designing, building, optimizing, and commissioning control systems for chiller plants, boiler plants, cogeneration facilities, energy transfer stations, electrical microgrids, and city-wide SCADA networks. Thermo Systems designs and deploys non-proprietary hardware and software solutions utilizing manufacturers such as Rockwell Automation, GE, OSI, Schneider Electric (Wonderware) and others.

Reduce energy costs and increase efficiency with the right full-service automation and information partner on your team.

Additional Energy Content

Life Sciences & Pharmaceuticals

Life Sciences automation experts since 1998

Since our inception in 1998, Thermo Systems has been providing best-in-class non-proprietary Building Automation System (BAS) solutions for clients with critical applications. Our solution features utilizing industrial control system technology such as PLC and SCADA systems. By implementing industrial controls, the end user gets the most reliable and repeatable technology on the market, a flexible and scalable system, and a truly non-proprietary system. For customers in regulated markets, our team provides the system life cycle documentation, traceability, and testing required to meet the FDA’s and other governing bodies’ regulations and guidelines.

Validated Systems Experience

Thermo Systems also deploys best-in-class validated Environmental Monitoring Systems (EMS) for our life sciences clients. All of our validated systems include the required documentation, programming, and testing as prescribed within the Good Automated Manufacturing Practices (GAMP) guideline. Similarly to our BAS solutions, we deploy our EMS solutions with industrial controls technology to ensure maximum uptime and overall performance. All validated EMS solutions are deployed with validated and nonproprietary historian servers that comply with 21 CFR Part 11 for electronic records.

A Focus on Quality

Our Quality Management System (QMS) governs our daily operation at all levels of the organization. The guidelines set forth by the QMS ensure that Thermo Systems provides high quality products and services to our clients while operating consistently and efficiently. The Quality Management System details the goals and values of Thermo Systems, the procedures in place to meet those goals and maintain those values, and our organizational structure. The QMS also describes the checks and balances in place to verify these procedures are being followed.

Mission Critical / Data Centers

Mission Critical Experience

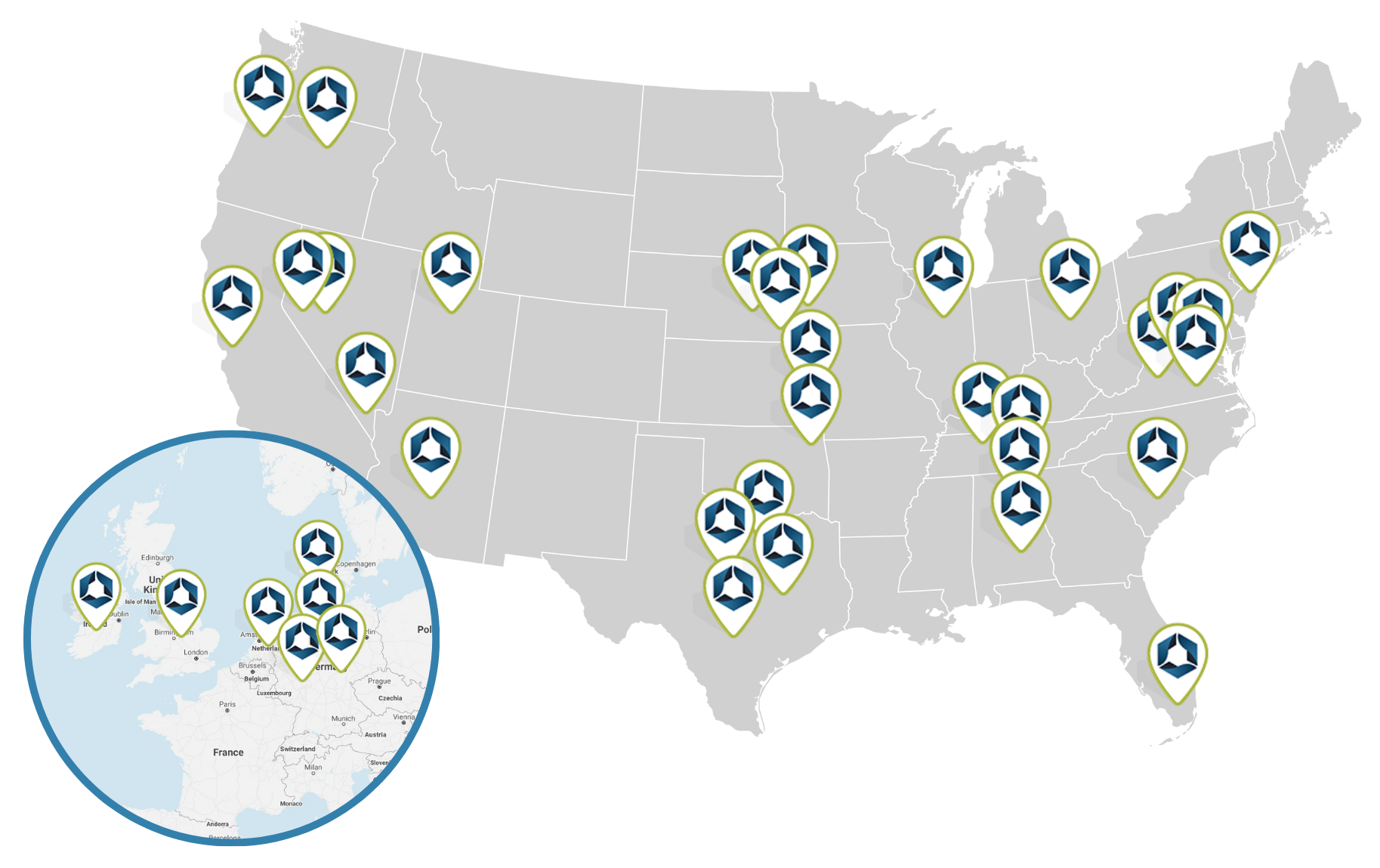

In recent years, the data center market has exploded and Thermo Systems has become a key part of the success story of some of the industry’s biggest players. Our Mission Critical team has a proven track record of executing the design and commissioning of projects at the hyperscale speed our clients demand. We have experienced personnel from technicians to project managers that understand the intense demands of the data center construction and commissioning schedule. In addition, Thermo Systems was founded on quality as a core principle, which aligns with the expectations of our mission critical partners. To date, Thermo has approximately 4 GW of combined data center construction experience (complete and under contract) in both the Hyperscale and Colocation mission critical space.

Mission Critical BAS & EPMS Experts

The data center industry is experiencing rapid growth, and Thermo Systems has extensive experience designing and installing the control systems to make their facilities and critical utilities both efficient and resilient. Thermo Systems provides automation engineering services to assist in the design, installation, and commissioning of the critical HVAC, industrial water treatment, and distribution and power monitoring control systems similar to the ones that are shown in this video.