Solutions

Service & Support

We are a life-cycle partner.

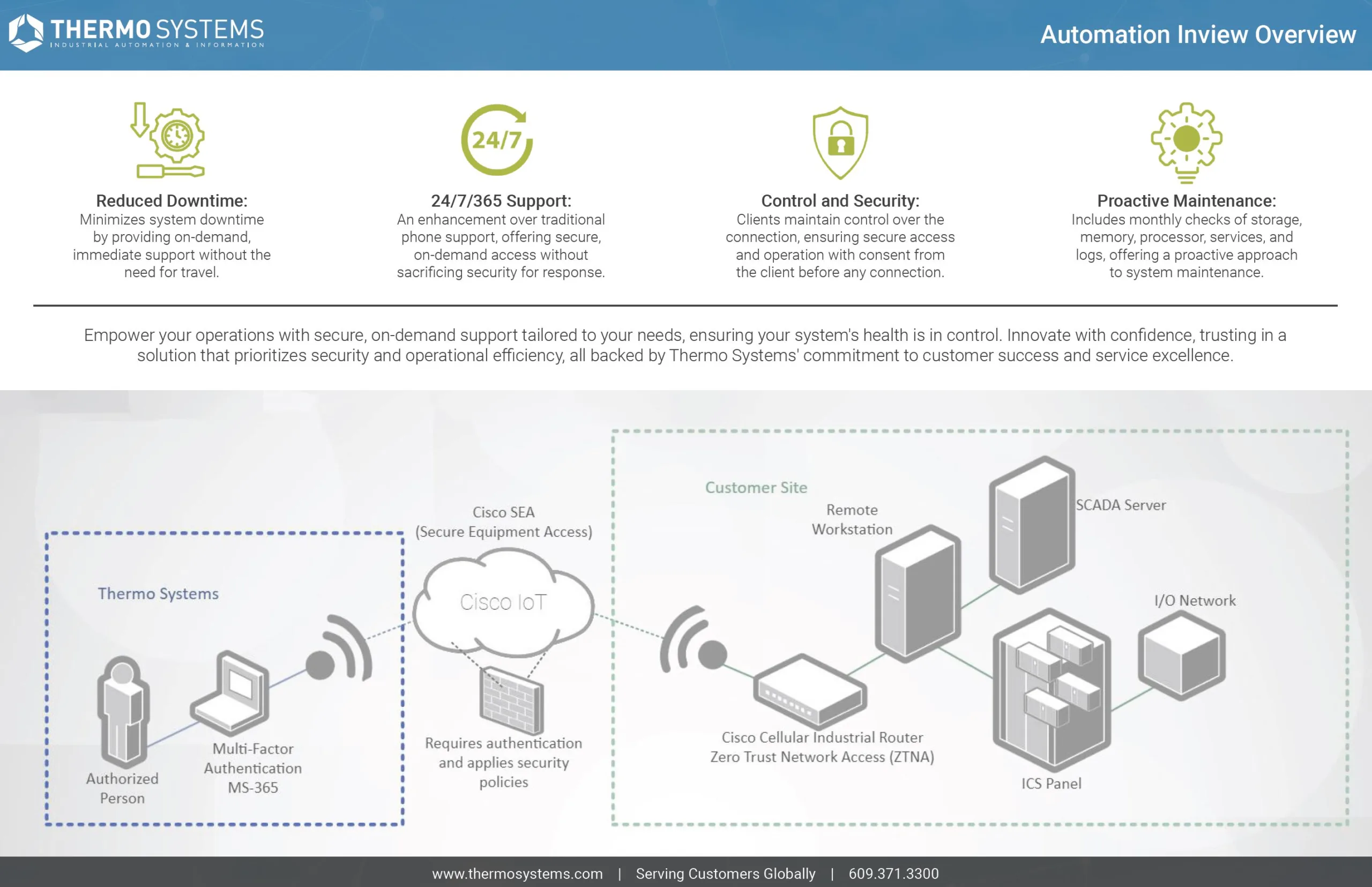

Automation InView

Remote Emergency Response/System Monitoring and Diagnostics

Automation InView is a secure, on-demand, remote connection that allows the Thermo Systems support team to securely connect to a client’s Industrial Control System (ICS). It is used for remote support, preventative maintenance, emergency response and advanced monitoring. To read more about Automation InView, view our full informational PDF.

OIT Services

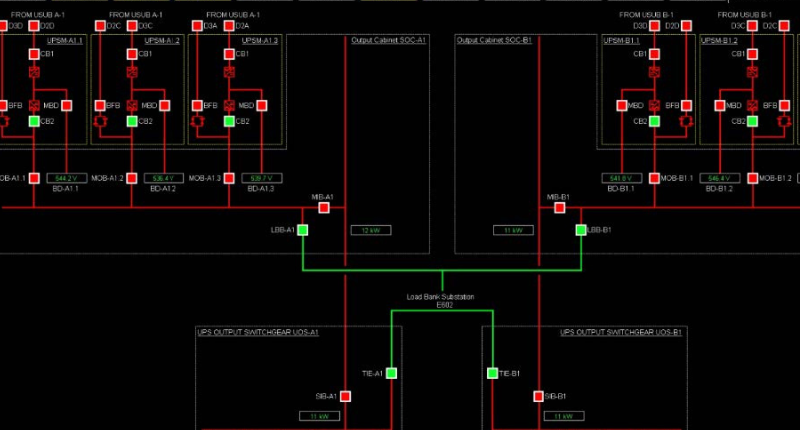

Industrial control system (ICS) resilience is critical at every phase of the system’s design, deployment, and operation.

Is your ICS resilient ?

Why partner with Thermo Systems for your ICS security and resiliency needs?

ICS Security Audit & Gap Analysis

Thermo Systems provides:

- Onsite and drawing surveys/reviews of your ICS to reveal possible physical and cyber gaps in the existing control system

- Reports highlighting the potential physical and cyber risks in the control system revealed in the audit

- An analysis of the gaps between the existing control system security status and industry standards

ICS Security Risk Management Plan

Thermo Systems creates a specification document detailing the implementation of gap remediation as derived from the Audit and Gap Analysis Report.

Our clients receive a comprehensive guide that focuses on best practices from industry standards to maintain ICS functionality and diminish physical and cyber attacks.

ICS Resiliency Implementation

Thermo Systems provides onsite implementation of the Risk Management Plan, including:

- Network access point physical/software locks

- Furnishing/installing firewalls, servers or other demilitarized zone equipment

- Control system application password protection and renewal plan

- Other onsite security engineering efforts.

Onsite implementation offerings are listed below.

ICS resiliency implementation measures include:

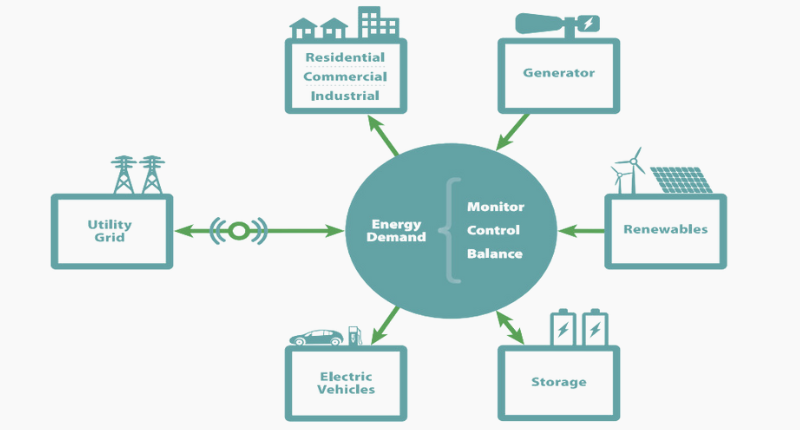

Microgrids

What is a Microgrid?

Thermo Systems’ Microgrid Experience

Benefits of Microgrids

Additional Microgrid Content

Building Automation Systems

What is a Building Automation System (BAS)?

BAS Terms

| Term | Definition |

|---|---|

| Building Management Systems (BMS) | BMS is essentially a synonym for BAS. A building management system will allow you to control all of the individual systems and processes within your facility. |

| Validated BAS | Typically used in the pharmaceutical and life sciences industry, a validated building automation system specifically refers to controlling those critical processes within the pharma and life sciences industries which can have an impact on meeting regulatory compliance, safety, and quality measures. |

| Mission-Critical BAS | “Mission-critical” operations refer to those processes that would have a detrimental impact to your facility if interrupted. These are often in pharmaceutical labs and packaging facilities, data centers that rely on cool environments, hospitals, and more. If power or HVAC utilities fail in these facilities, there is often massive loss of product, capital, data, etc. |

| Qualified BAS (QBAS) | Closed loop control and monitoring of temperature, pressure, humidity, and more. Like Validated BAS, these systems have to meet specific compliance measures and often involve monitoring, reporting, and data historians. |

| Environmental Monitoring System (EMS) | These sytems also focus on temperature, pressure, humidity, etc. of a controlled environment like labs, manufacturing facilities, and data centers. |

Why might you need a BAS?

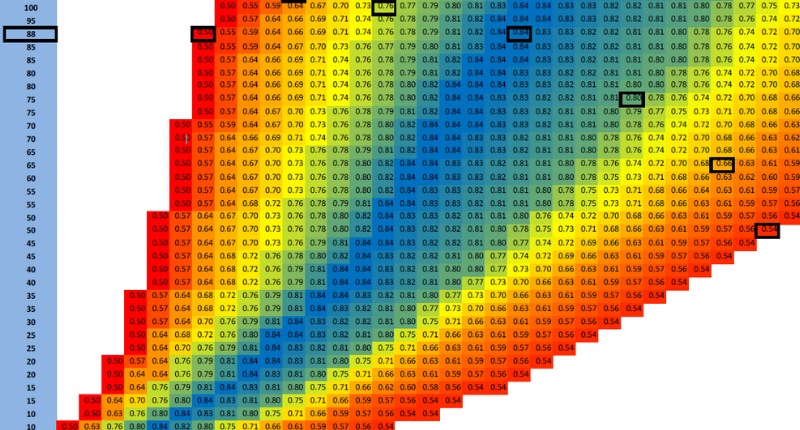

Industrial Optimization

Reduce energy costs and increase efficiency while prioritizing safety and uptime.

Energy Audit

As a first step, we perform an ASHRAE Level 1, 2, or 3 site survey at your facility. Following the audit, Thermo Systems will recommend Energy Conservation Measures (ECMs) and detail the scope, cost, and return on investment (ROI) of each possible energy-saving project.

Execution of ECMs

Once you choose an ECM initiative, Thermo Systems can manage your project from start to finish. We take a turnkey approach, overseeing everything from design to construction. In addition, we take the extra step to investigate and manage all possible utility rebates and incentives.

Advanced Visualization

Once the ECMs are successfully executed, we will provide you with an energy dashboard and reporting system. Thermo Systems will teach you how to read the detailed data from your system, allowing you to see your results in real time.

Measurement & Verification

Lastly, Thermo Systems will perform measurement and verification (M&V) on your newly-optimized system. We will continue periodic M&V throughout a year's worth of seasonal climate changes to allow for operational and tuning adjustments. M&V real-time and historical trending data will prove reductions in energy usage to support ROI and utility rebate programs.

Some example Energy Conservation Measures (ECMs) include: