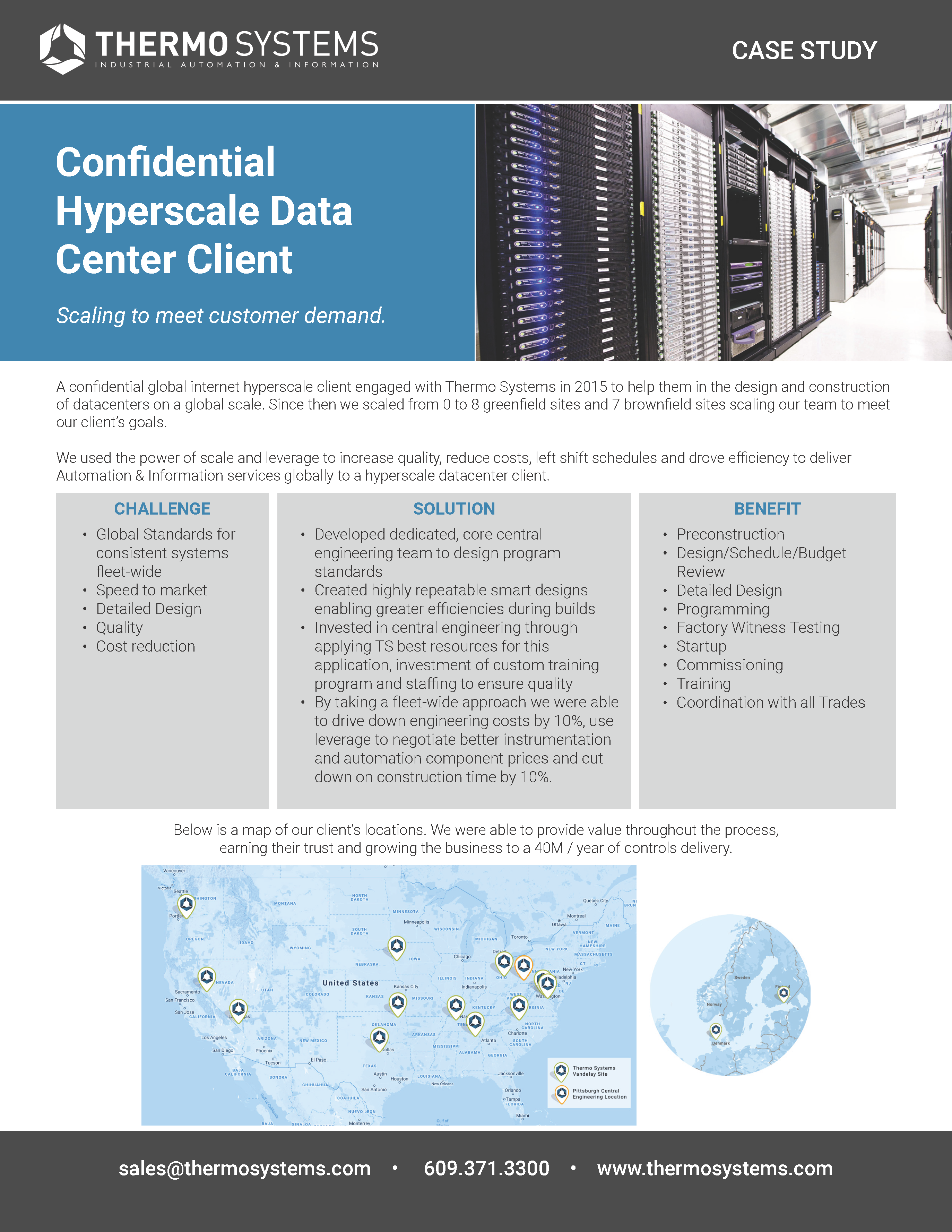

A confidential global internet hyperscale client engaged with Thermo Systems in 2015 to help them in the design and construction of datacenters on a global scale. Since then we scaled from 0 to 8 greenfield sites and 7 brownfield sites scaling our team to meet our client’s goals.

We used the power of scale and leverage to increase quality, reduce costs, left shift schedules and drove efficiency to deliver Automation & Information services globally to a hyperscale datacenter client.

CHALLENGE

- Global Standards for consistent systems fleet-wide

- Speed to market

- Detailed Design

- Quality

- Cost reduction

SOLUTION

- Developed dedicated, core central engineering team to design program standards

- Created highly repeatable smart designs enabling greater efficiencies during builds

- Invested in central engineering through applying TS best resources for this application, investment of custom training program and staffing to ensure quality

- By taking a fleet-wide approach we were able to drive down engineering costs by 10%, use leverage to negotiate better instrumentation and automation component prices and cut down on construction time by 10%.

BENEFIT

- Preconstruction

- Design/Schedule/Budget Review

- Detailed Design

- Programming

- Factory Witness Testing

- Startup

- Commissioning

- Training

- Coordination with all Trades

Below is a map of our client’s locations. We were able to provide value throughout the process, earning their trust and growing the business to a 40M / year of controls delivery.